| Performance | | | | | | | | |

| Nominal heat output central heating operation @ 80/60°C kW (min–max)* | 8.0 - 29.8 | 8.0 - 40.8 | 12.0 - 55.3 | 12.0 - 61.5 | 14.1 - 84.2 | 18.9 - 103.9 | 31.5 - 128.1 | 31.5 - 152.1 |

| Nominal heat output central heating operation @ 50/30°C kW (min–max)* | 9.1 - 30.9 | 9.1 - 42.4 | 13.5 - 58.6 | 13.5 - 65.0 | 15.8 - 89.5 | 21.2 - 109.7 | 34.7 - 136.1 | 34.7 - 161.6 |

| Nominal input (Hi) (min–max) kW | 8.2 - 30.0 | 8.2 - 41.2 | 12.2 - 56.5 | 12.2 - 62.0 | 14.6 - 86.0 | 19.6 - 107.0 | 32.0 - 131.0 | 32.0 - 156.0 |

| Efficiency | | | | | | | | |

| SBEM seasonal efficiency GCV % | 97.5 | 97.6 | 96.0 | 97.5 | 95.6 | 95.4 | 96.1 | 95.9 |

| Efficiency – full load 100% NCV % | 99.4 | 99.1 | 97.8 | 99.2 | 97.9 | 97.1 | 97.8 | 97.5 |

| Efficiency – part load 30% NCV % | 110.4 | 110.6 | 108.7 | 110.4 | 108.1 | 108.0 | 108.8 | 108.5 |

| Eco design useful efficiency@ 80/60°C (100% full load) GCV % | 89.6 | 89.3 | 88.1 | 89.4 | 88.2 | 87.5 | 88.1 | 87.8 |

| Eco design useful efficiency @ 50/30°C(30% part load) GCV % | 99.5 | 99.6 | 97.9 | 99.5 | 97.4 | 97.3 | 98.0 | 97.8 |

| Energy labelling seasonal space efficiency GCV % | 94 | 94 | 92 | 94 | N/A | N/A | N/A | N/A |

| ErP efficiency rating | A | A | A | A | N/A | N/A | N/A | N/A |

| Annual energy consumption Gj | 91 | 125 | 173 | 188 | N/A | N/A | N/A | N/A |

| Gas | | | | | | | | |

| Standard fuel | Natural Gas | Natural Gas | Natural Gas | Natural Gas | Natural Gas | Natural Gas | Natural Gas | Natural Gas |

| Optional fuel adjustment – see installation and service manual | LPG(Propane) | LPG(Propane) | LPG(Propane) | LPG(Propane) | LPG(Propane) | LPG(Propane) | LPG(Propane) | LPG(Propane) |

| Min / Max Gas consumption NG m3/h | 0.8 - 3.1 | 0.8 - 4.3 | 1.3 - 5.9 | 1.3 - 6.5 | 1.5 - 9.0 | 2.0 - 11.1 | 3.4 - 13.9 | 3.4 - 16.5 |

| Min / MaxGas consumption LPG m3/h | 0.3 - 1.2 | 0.3 - 1.6 | 0.5 - 2.2 | 0.5 - 2.4 | 0.6 - 3.4 | 0.8 - 4.2 | 1.4 - 5.3 | 1.4 - 6.3 |

| Min/max gas inlet pressure NG mbar | 17 - 25 | 17 - 25 | 17 - 25 | 17 - 25 | 17 - 25 | 17 - 25 | 17 - 25 | 17 - 25 |

| Min/max gas pressure LPG mbar | 37 - 50 | 37 - 50 | 37 - 50 | 37 - 50 | 37 - 50 | 37 - 50 | 37 - 50 | 37 - 50 |

| Gas connection size BSP inches | 3/4 male thread(22mm) | 3/4 male thread(22mm) | 3/4 male thread(22mm) | 3/4 male thread(22mm) | 3/4 male thread(22mm) | 3/4 male thread(22mm) | 1 male thread(28mm) | 1 male thread(28mm) |

| Flue | | | | | | | | |

| Flue diameter mm I/D | 80 | 80 | 100 | 100 | 100 | 100 | 100 | 100 |

| Air inlet diameter mm I/D | 125 | 125 | 150 | 150 | 150 | 150 | 150 | 150 |

| Min/max flue gas mass flow ratekg/h | 14 - 50 | 14 - 69 | 21 - 93 | 21 - 104 | 28 - 138 | 36 - 178 | 57 - 233 | 57 - 277 |

| Min / Max flue gas temperature °C | 30 - 65 | 30 - 67 | 30 - 68 | 30 - 68 | 30 - 68 | 30 - 72 | 32 - 63 | 32 - 66 |

| Max counter pressure Pa | 70 | 150 | 120 | 100 | 160 | 220 | 200 | 200 |

| Hydraulics | | | | | | | | |

| Water content litres | 4.3 | 4.3 | 6.4 | 6.4 | 9.4 | 9.4 | 17 | 17 |

| Hydraulic resistance @ 15°C ∆T mbar | 124 | 203 | 231 | 290 | 272 | 444 | 224 | 302 |

| Hydraulic resistance @ 20°C ∆T mbar | 70 | 114 | 130 | 163 | 153 | 250 | 126 | 170 |

| Nominal flow rate @ 15°C ∆T l/s | 0.48 | 0.65 | 0.88 | 0.98 | 1.34 | 1.66 | 2.04 | 2.43 |

| Nominal flow rate @ 20°C ∆T l/s | 0.36 | 0.49 | 0.66 | 0.74 | 1.01 | 1.24 | 1.53 | 1.82 |

| Condensate connection (mm) dia | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 32 | 32 |

| Connection size (mm) dia | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 1 1/4 male thread(32mm) | 1 1/4 male thread(32mm) |

| Standard operating temperature** °C | 20 - 90 | 20 - 90 | 20 - 90 | 20 - 90 | 20 - 90 | 20 - 90 | 20 - 90 | 20 - 90 |

| Max operating temperature °C | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| High limit temperature °C | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 |

| Max water operating pressure bar | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Min water operating pressure bar | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Min operating pressure bar (OV)** | 0.3 o/v | 0.3 o/v | 0.3 o/v | 0.3 o/v | 0.3 o/v | 0.3 o/v | N/A | N/A |

| General | | | | | | | | |

| Total weight (including packaging) kg | 61 | 61 | 67 | 67 | 76 | 77 | 147 | 147 |

| Min mounting weight without front panel kg | 52 | 52 | 58 | 58 | 67 | 68 | 123 | 123 |

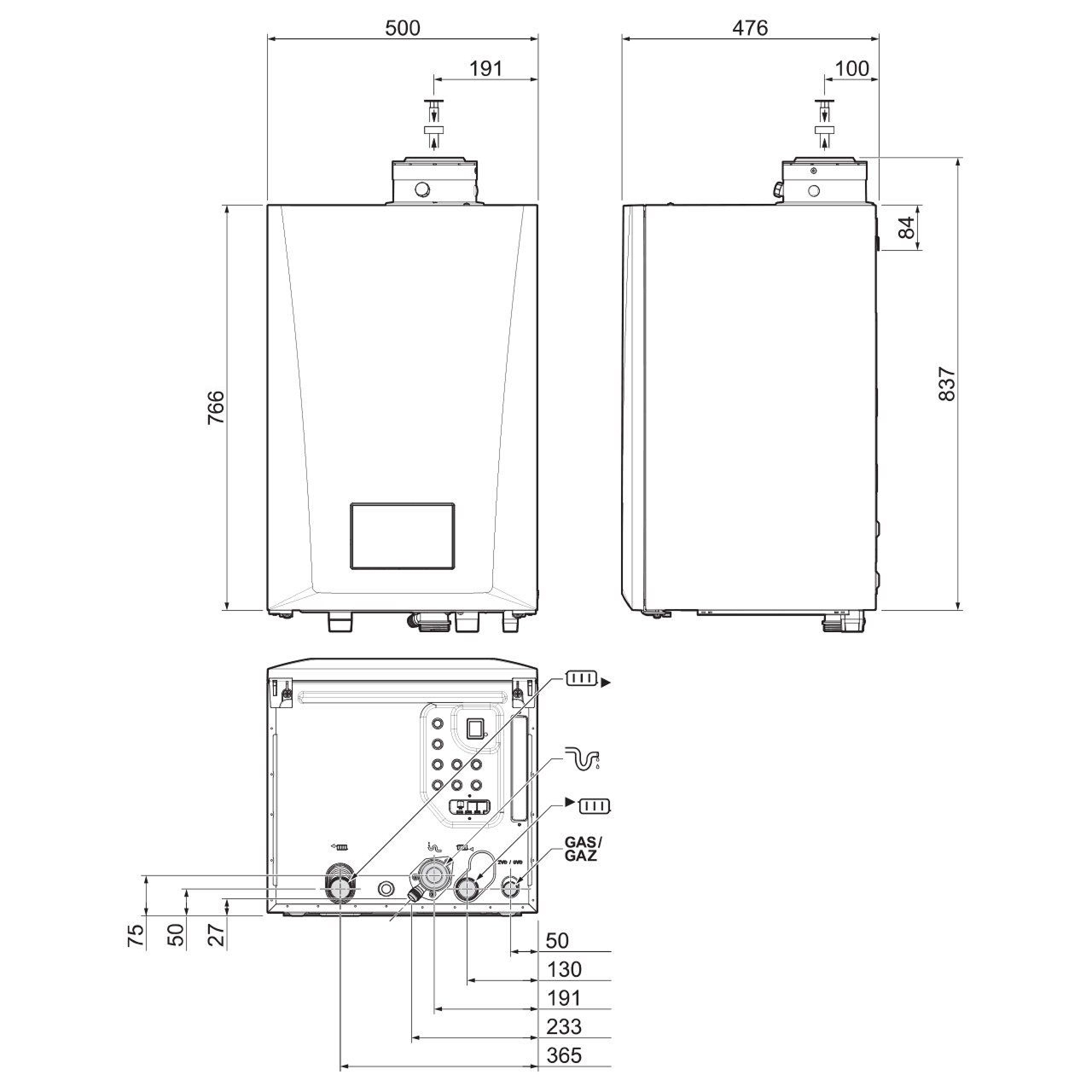

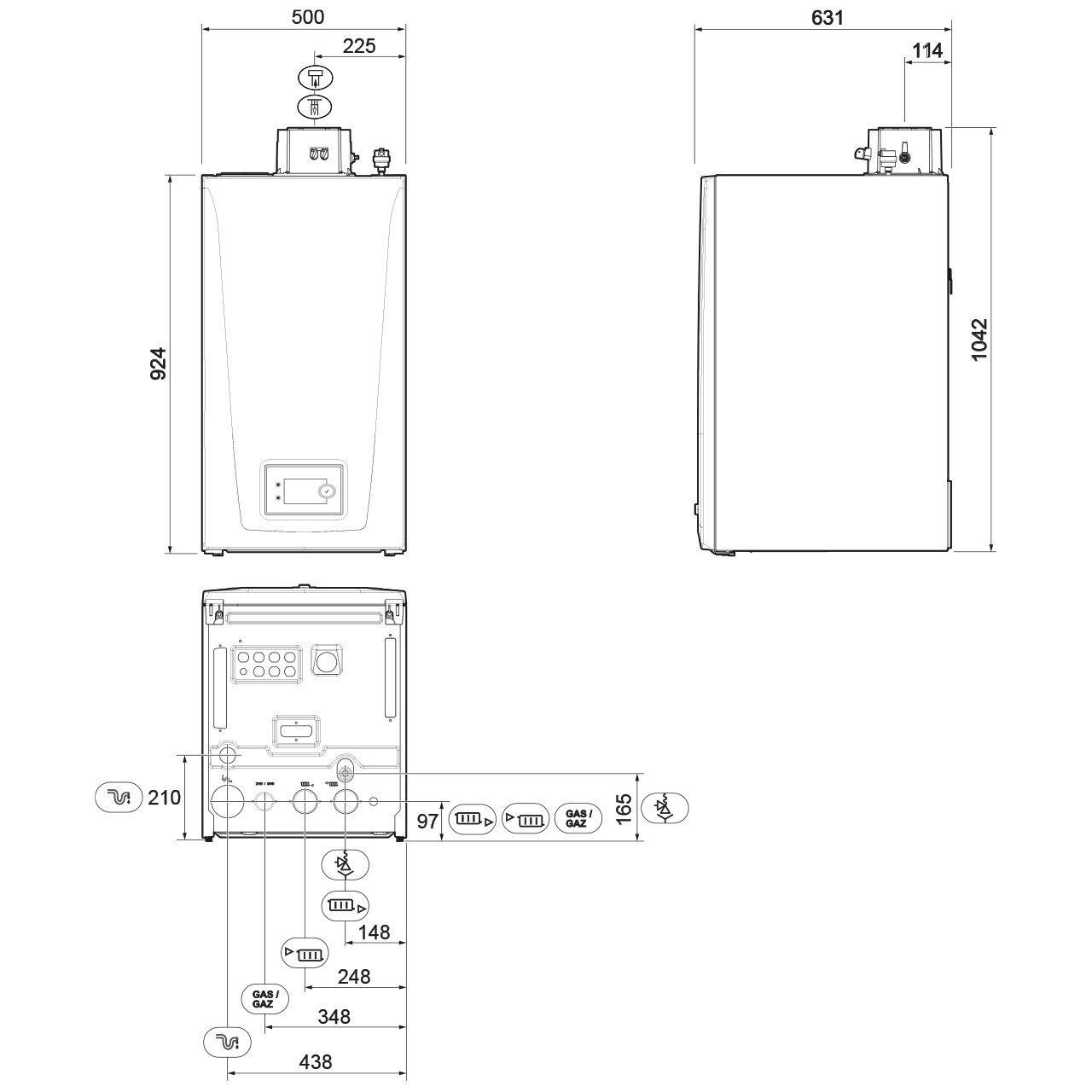

| Dimension mm (WxHxD) | 500 x 750 x 476 | 500 x 750 x 476 | 500 x 750 x 476 | 500 x 750 x 476 | 500 x 750 x 476 | 500 x 750 x 476 | 600 x 1045 x 602 | 600 x 1045 x 602 |

| NOx Annual Emissions BREEAM EN15502 – NG mg/kWh (dry, 0% O2) Class 6*** | 24 | 24 | 23 | 23 | 23 | 23 | 24 | 22 |

| BREEAM Credits *** | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Noise levels dB(A) at 1 metre | 38.3 | 45.1 | 46.7 | 46.7 | 51.6 | 51.1 | 59.5 | 59.5 |

| Eco design sound power levels LWA indoors dB | 46 | 53 | 55 | 55 | 60 | 59 | 68 | 68 |

| Standby heat loss kW | 0.101 | 0.101 | 0.110 | 0.110 | 0.123 | 0.123 | 0.191 | 0.191 |

| Electrical | | | | | | | | |

| Nominal power supply | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz | 230v x 1ph x 50hz |

| Min / Max Power consumption w | 18 - 36 | 18 - 71 | 22 - 69 | 23 - 83 | 23 - 111 | 19 - 169 | 47 - 199 | 47 - 275 |

| Modulating input v dc | 0 - 10 | 0 - 10 | 0 - 10 | 0 - 10 | 0 - 10 | 0 - 10 | 0 - 10 | 0 - 10 |

| Controls voltage (Potential free Contact) | 0 Volts | 0 Volts | 0 Volts | 0 Volts | 0 Volts | 0 Volts | 0 Volts | 0 Volts |

| Electrical protection index VAC (1) | X4D | X4D | X4D | X4D | X4D | X4D | X1B | X1B |